It seemed like a great alternative to the traditional friable alumina wheels because they don t generate a lot of heat they never need truing they cut more consistently and have a much longer usable lifespan.

Adjustable tool rest on a bench grinder should be positioned.

For ease of use and holding power these locks just can t be beat.

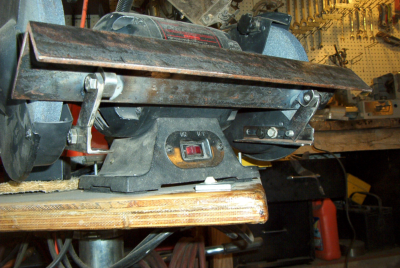

Bench grinder tool rest.

Perform a ring test on the wheel.

The square tube arms slide in well machined channels on the base and lock in place with oversized handles.

The adjustable tools rest on a bench grinder should be positioned.

Ring test a good way to check the condition of the grinding wheel on a bench grinder is to.

The sander comes with an adjustable tool holder that allows you to attach a sanding arm or a tool rest in the front.

This comes in handy if you are needing to sit the tool down to adjust the speed of the grinder or if you need to change out a wheel.

Bench grinder tool rests.

A grinder can catch on rough material edges and shift around especially when using rotary bits called.

To make it more efficient the 10 inch driver wheel has a rubber face for a better grip.

Perform a ring test on the wheel a good way to check the condition of the grinding wheel on a bench grinder is to.

The adjustable tool rest on a bench grinder should be positioned inch from the wheel.

This is used to place the tool you are working on to when not using it.

The adjustable tool rest on a bench grinder should be positioned.

A good way to check the condition of the grinding wheel on a bench grinder is to.

Edge the adjustable tool rest on a bench grinder should be positioned inch from the wheel.

1 8 inch from the grinder wheel.

When using a grinder try to work on the of the wheel whenver possible.

No matter the project you are on it will surely give ample advantage over other grinders.

The last part of getting into different types of wheels is the tool rest.

1 8 some manufacturers suggest that each time you use a pneumatic nailer the air inlet needs.

Also if you are wanting to just sharpen a.